Whether it’s a stand-alone compressor, an OTR diesel, or simply improving the efficiency of your engine, Total Seal® provides a wide selection of ring sets and custom piston rings for nearly every type of engine on the planet .

Over 50 years ago we invented the Gapless® piston ring that changed the industry. Today, we are much more than Gapless®. We design and manufacture piston rings for every type of internal combustion engine.

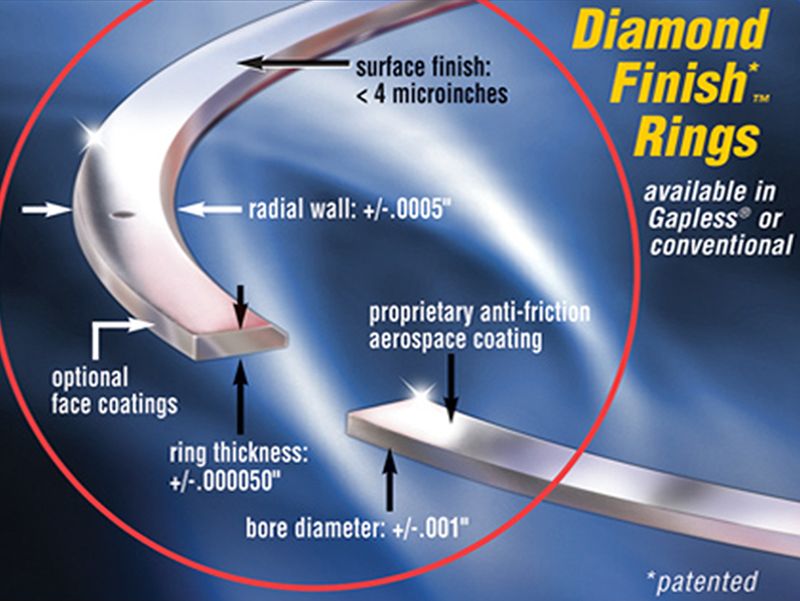

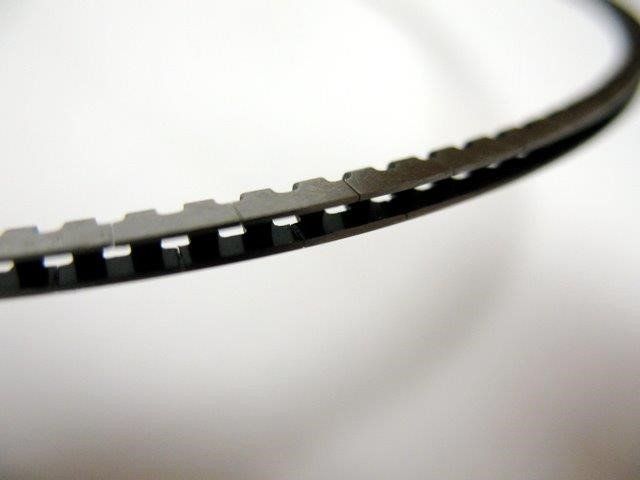

Conventional Gap, Gas-Ported, Total Conform™, Diamond Finish™, Gapless® and so many more. Our leading piston ring designs are made from Ductile Iron, Cast Iron, Stainless Steel or Tool Steel. We offer a variety of face coatings including Molybdenum, DLC and multiple PVD coatings.

A piston can only perform as well as the rings surrounding it do.

A piston can only perform as well as the rings surrounding it do.

We tailor ring sets to the specific needs of an engine. As a result, that engine runs more efficiently. Our piston rings have been improving the efficiency of race engines in every form of motorsports for decades, but we also do it for compressors, aviation, and agricultural engines, as well as any engine that has piston rings. Utilizing piston ring design to greatly increase engine efficiency is what we do best.

If engines work to make profit for your company, we can help those engines make more money for you. We’d love to discuss any of the options you may need directly with you.

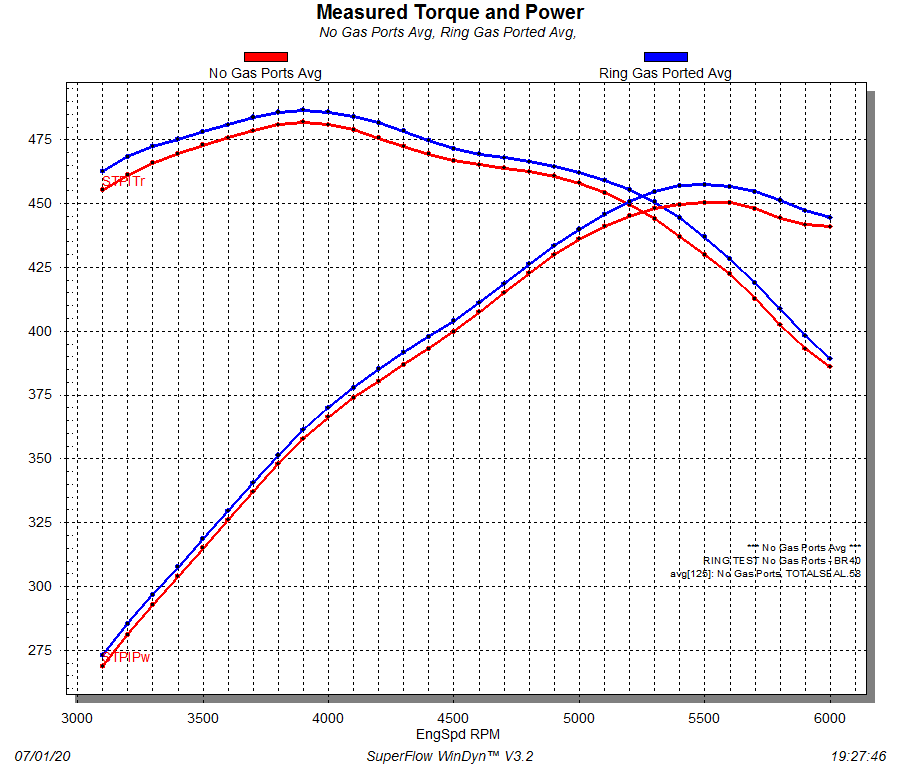

More Power AND More Savings

Engines that consume less fuel and compressors that draw less current would save a company on fuel and energy costs over time, especially with today’s fuel costs.

Engines and compressors that last longer obviously save money by reducing replacement/rebuild costs.

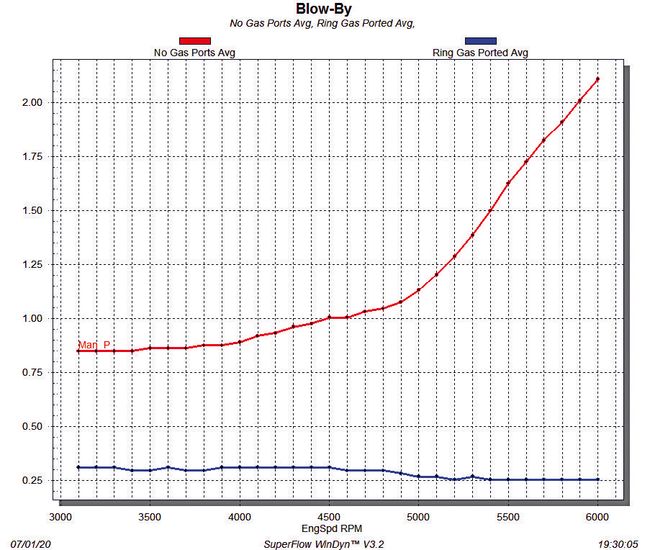

Engines with less blow-by enable longer engine oil life, which can save money through fewer oil changes (both in labor and oil costs).

With inflation driving up the cost of materials and labor, isn’t now the best time to look for areas to improve efficiency?

Well, the number one source of friction and wear in engines are the piston rings rubbing against the cylinder walls. Multiple research studies from FORD and the US Department of Energy have concluded that the piston ring and cylinder wall account for as much as 40% of all engine friction. No wonder today’s OEM engines have thinner piston rings than their predecessors.

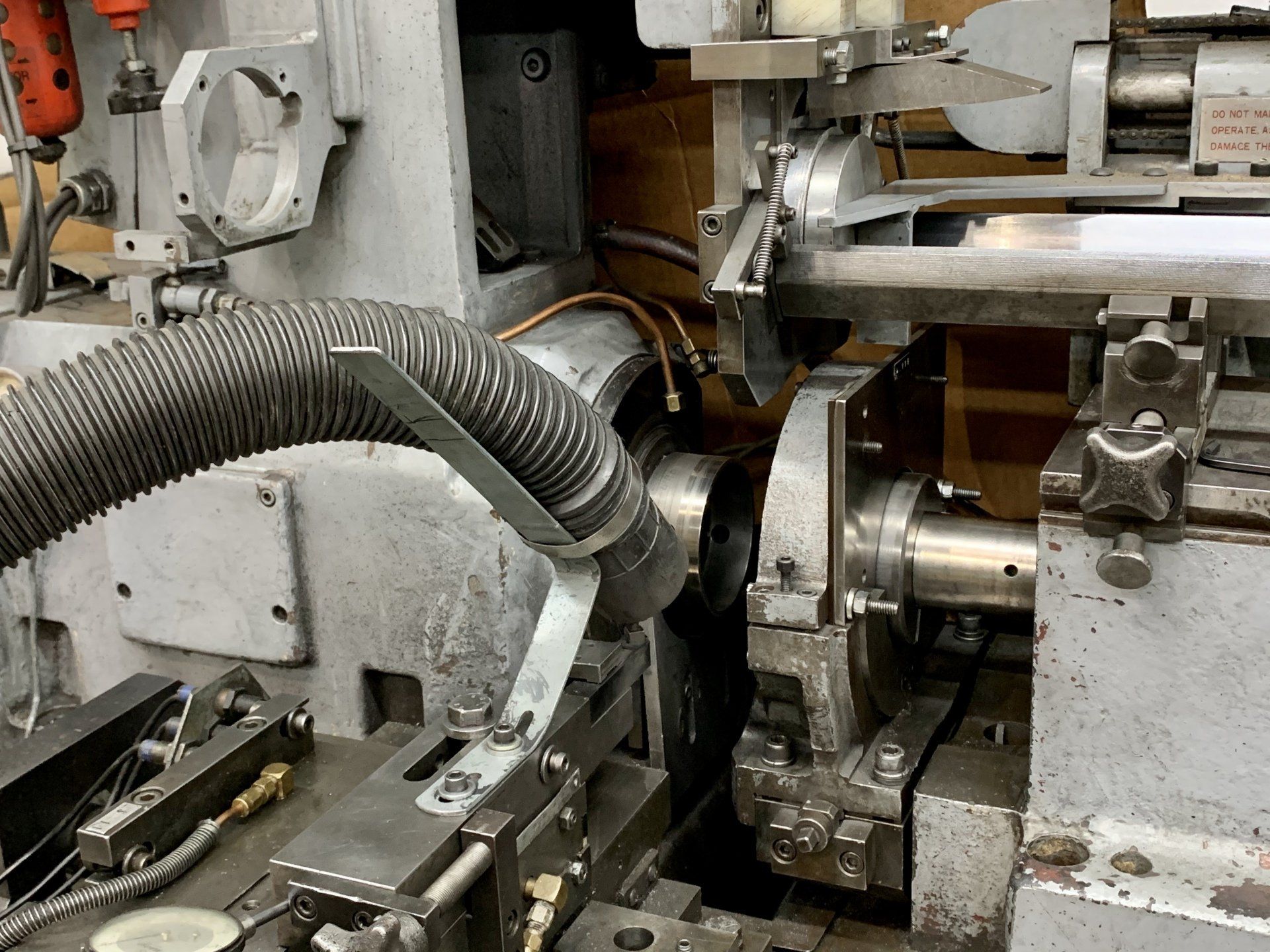

Custom Ring Production

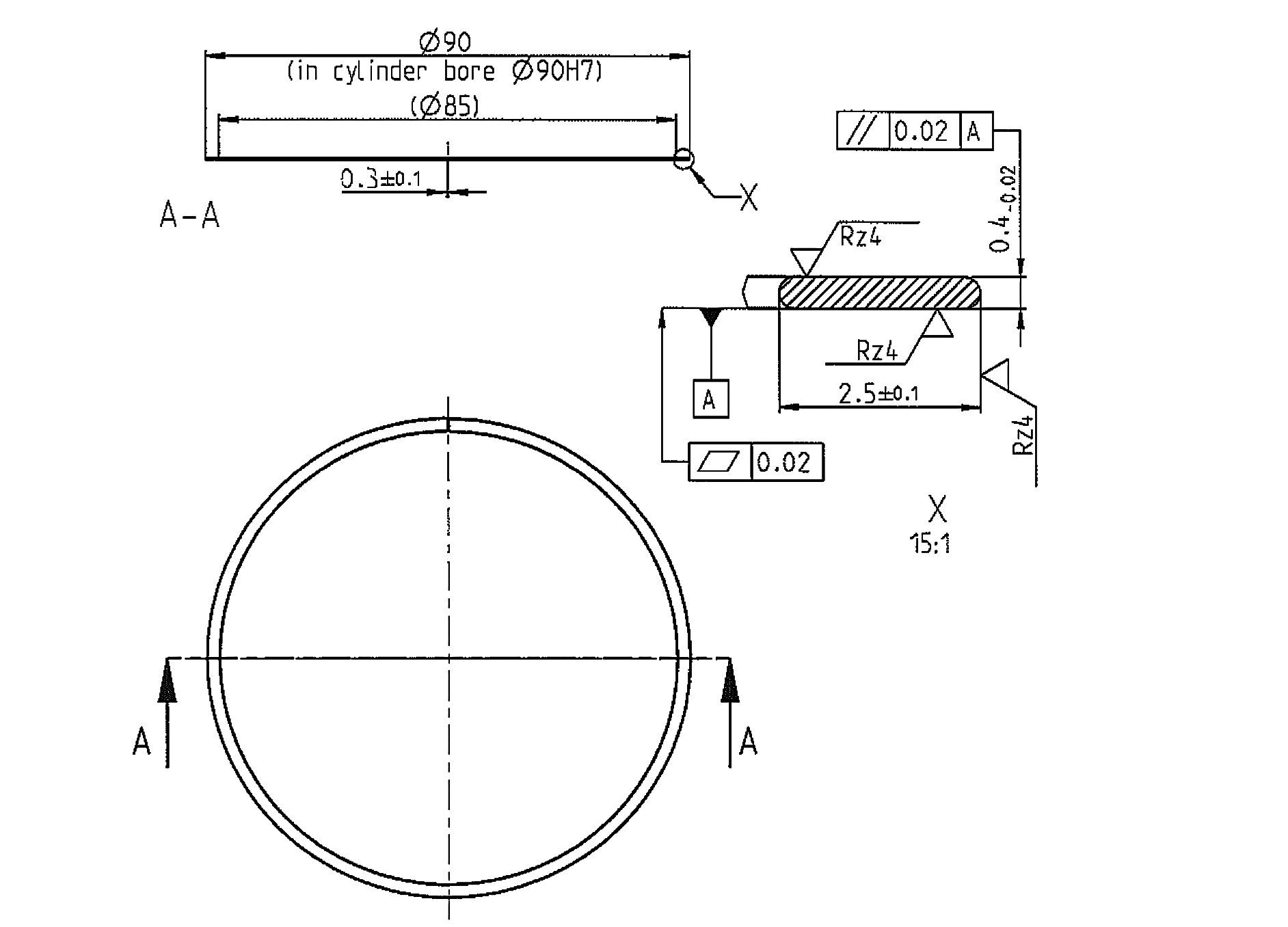

Made to Order

If our inventory of over 10,000 ring sizes doesn’t fit your application, we can produce rings specific to your needs, and we don’t require minimum runs of 100,000 pieces. Our in-house engineering, design and manufacturing on our own custom machinery allows us to turn your order quickly, efficiently and perfectly - every time. Total Seal® supplies Made To Order rings to keep your equipment not only running, but running more efficiently.

We Offer

- Reproduction of Existing Rings

- Production from Drawings

- Designed From Scratch

Custom Rings

Made to Order

If our inventory of over 10,000 ring sizes doesn’t fit your application, we can produce rings specific to your needs, and we don’t require minimum runs of 100,000 pieces. Our in-house engineering, design and manufacturing on our own custom machinery allows us to turn your order quickly, efficiently and perfectly - every time. Total Seal® supplies Made To Order rings to keep your equipment not only running, but running more efficiently.

We Offer

- Reproduction of Existing Rings

- Production from Drawings

- Designed From Scratch

The Next Evolution in Piston Ring Technology

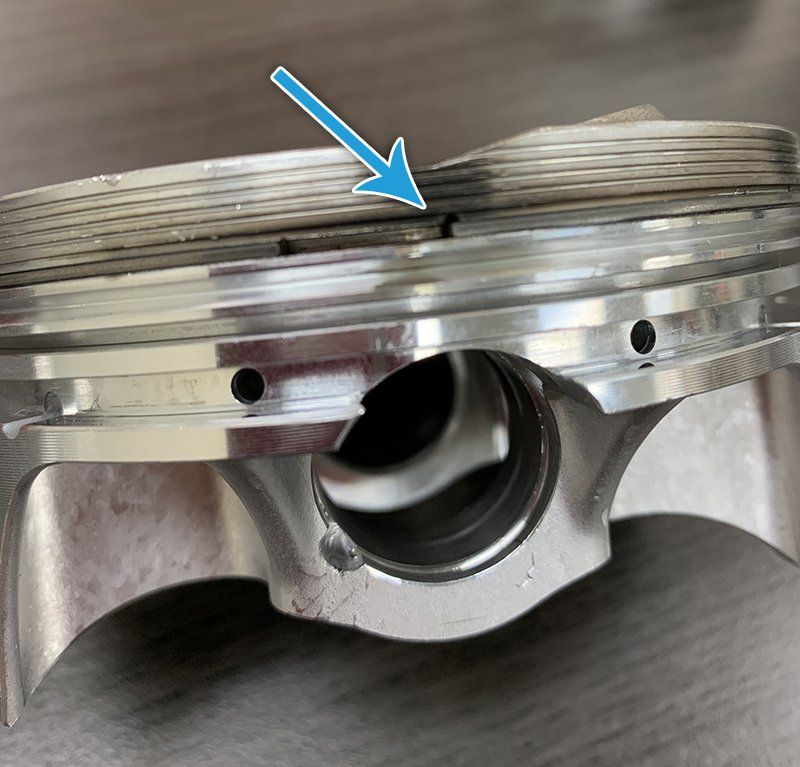

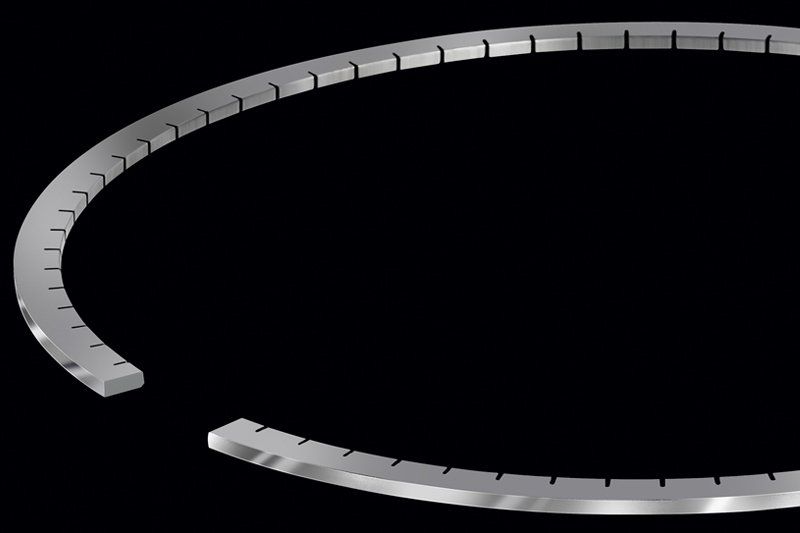

GAS-PORTED

Piston Rings

The primary job of the piston ring is to create the seal between the piston and the cylinder wall. Our new Gas-Ported piston rings represent an evolution in ring seal. The conventional practice of thick, heavy, high tension rings that fought against cylinder pressure to maintain seal has been revolutionized. Instead of fighting cylinder pressure, gas ported rings harness those forces and use them to improve ring seal. These advanced rings benefit all engines, especially turbocharged and supercharged engines.

Gas-ported performance without gas-ported pistons

Features strategically sized and placed horizontal slots in the ring allowing combustion gas to enter through the groove and behind the ring to gas-load the ring providing greatly improved ring sealing.

Extensively tested in virtually every form of engine with the same increases in ring sealing time after time.

Applications are available in both steel and ductile iron for top ring placements. When ordering simply ask for Gas-Ported on your top ring sets.

Links

Contact Information

All Rights Reserved | Total Seal Piston Rings