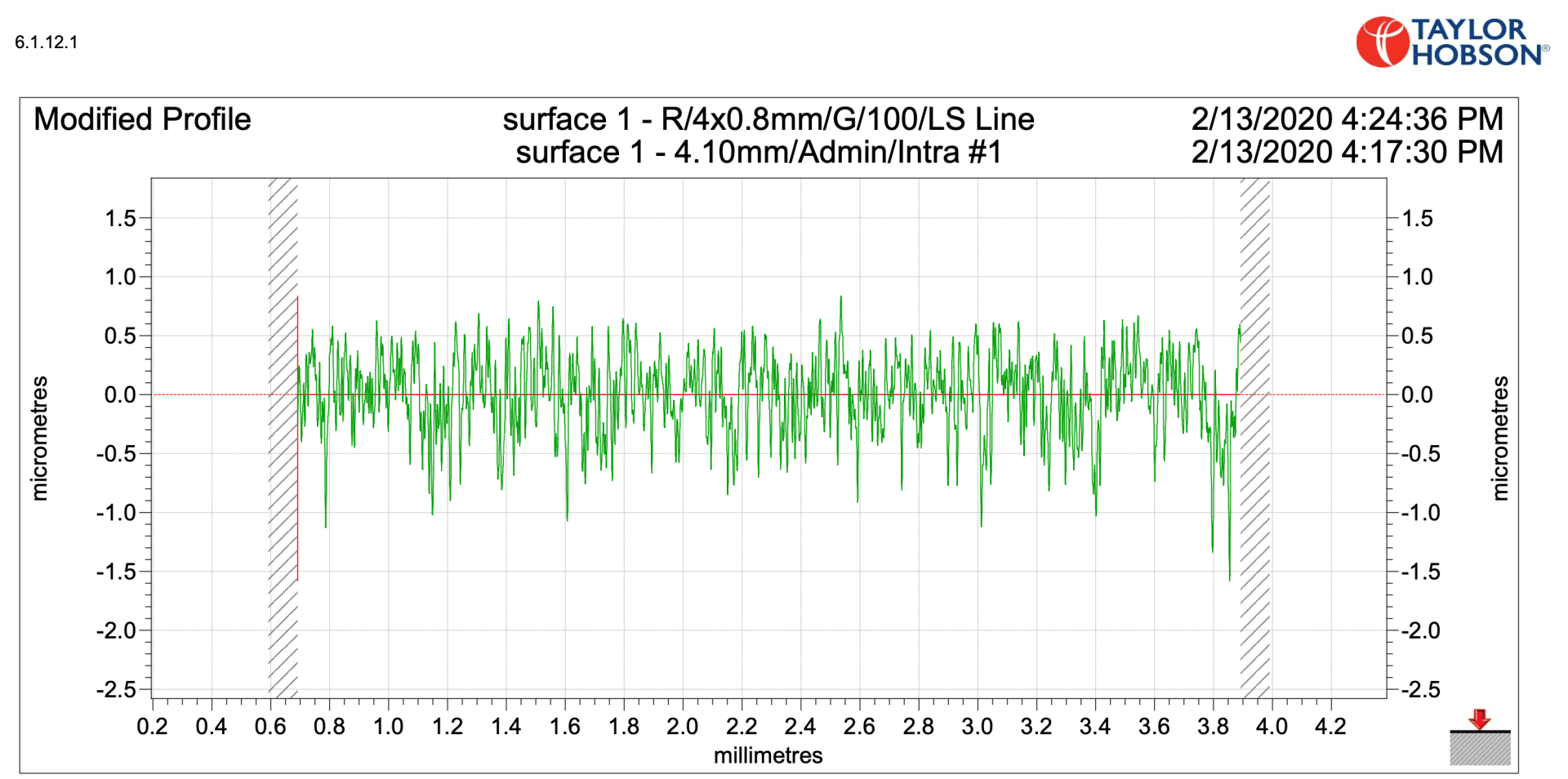

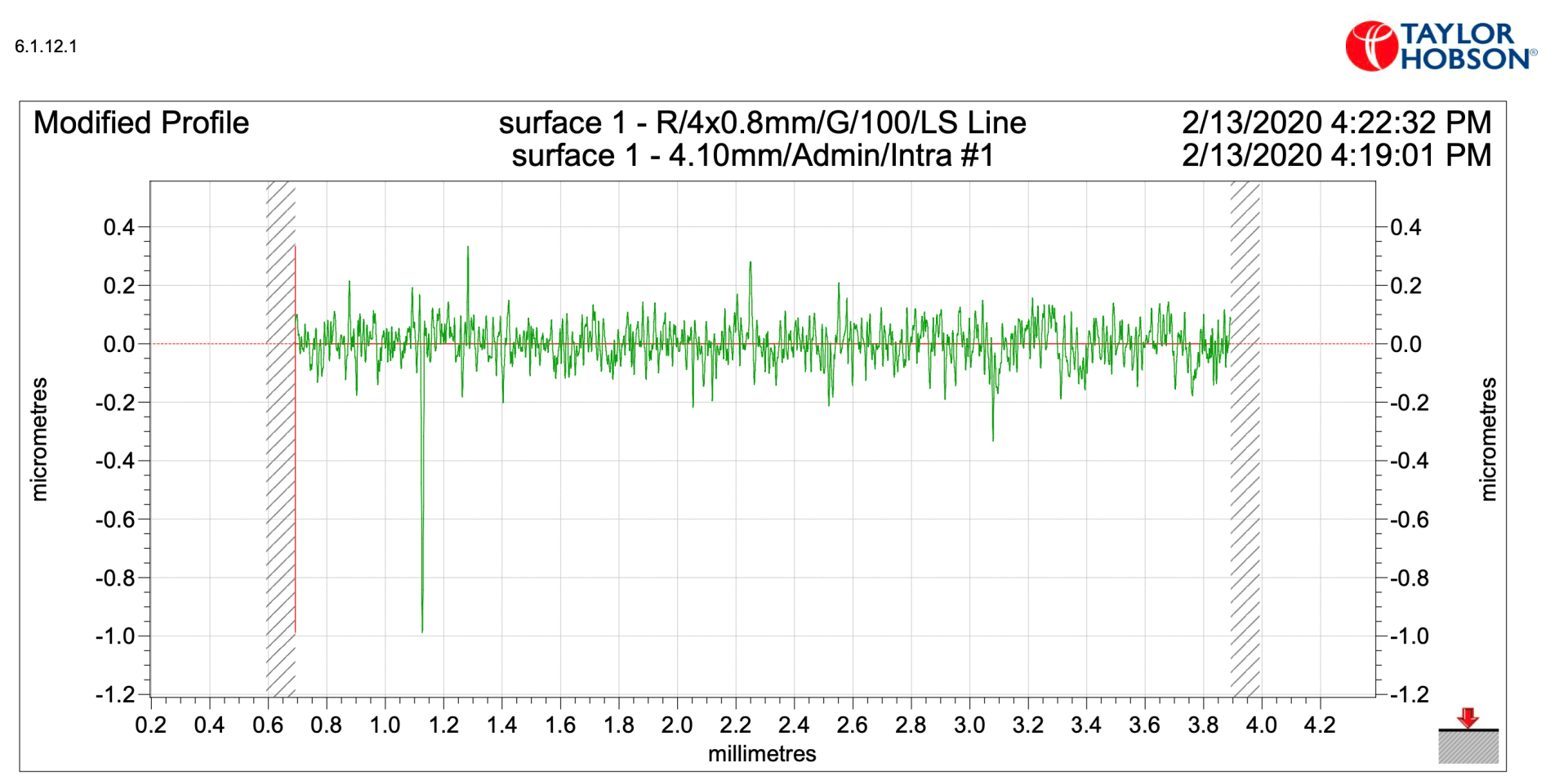

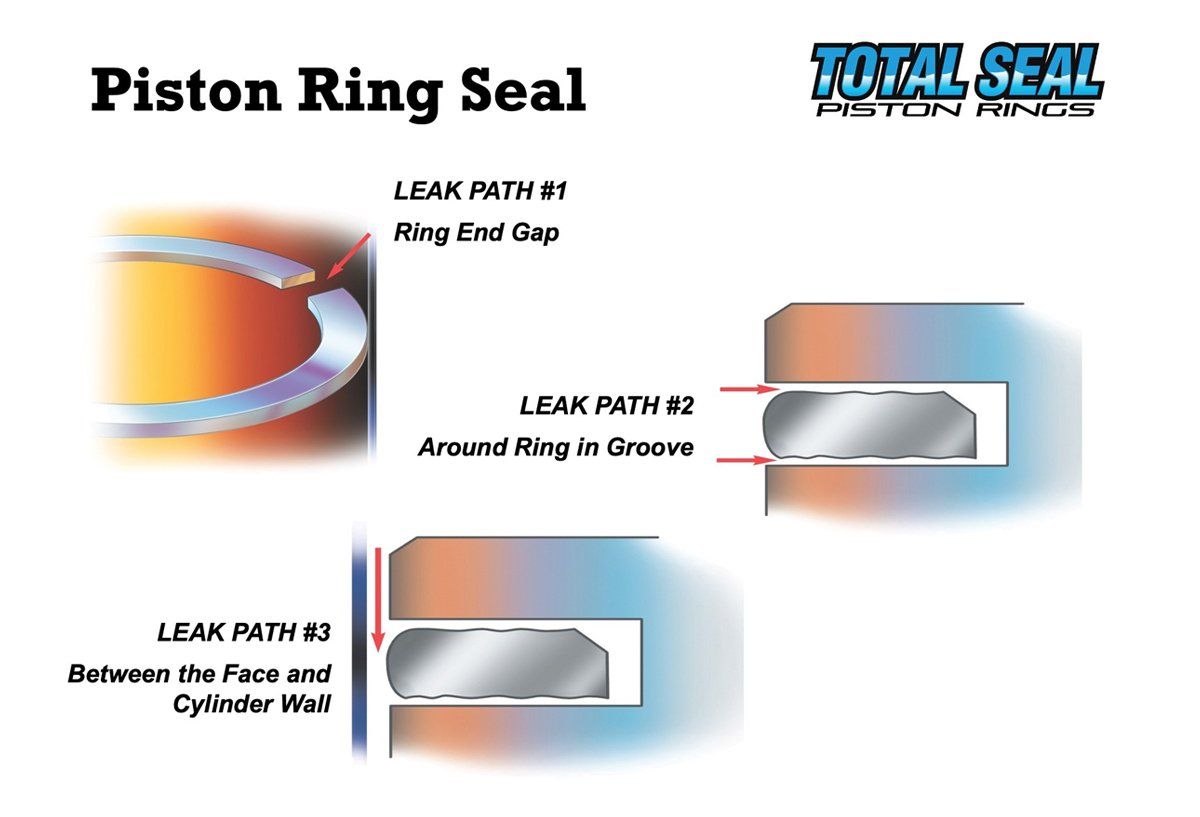

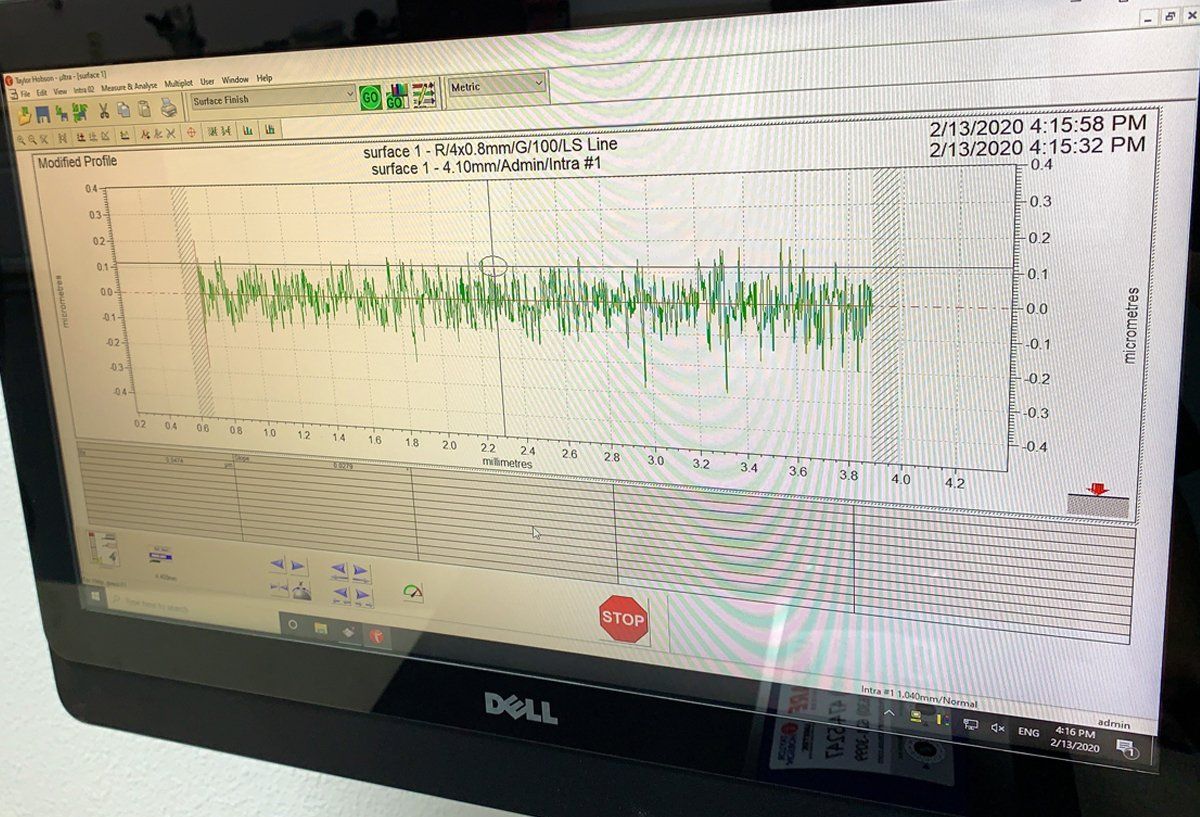

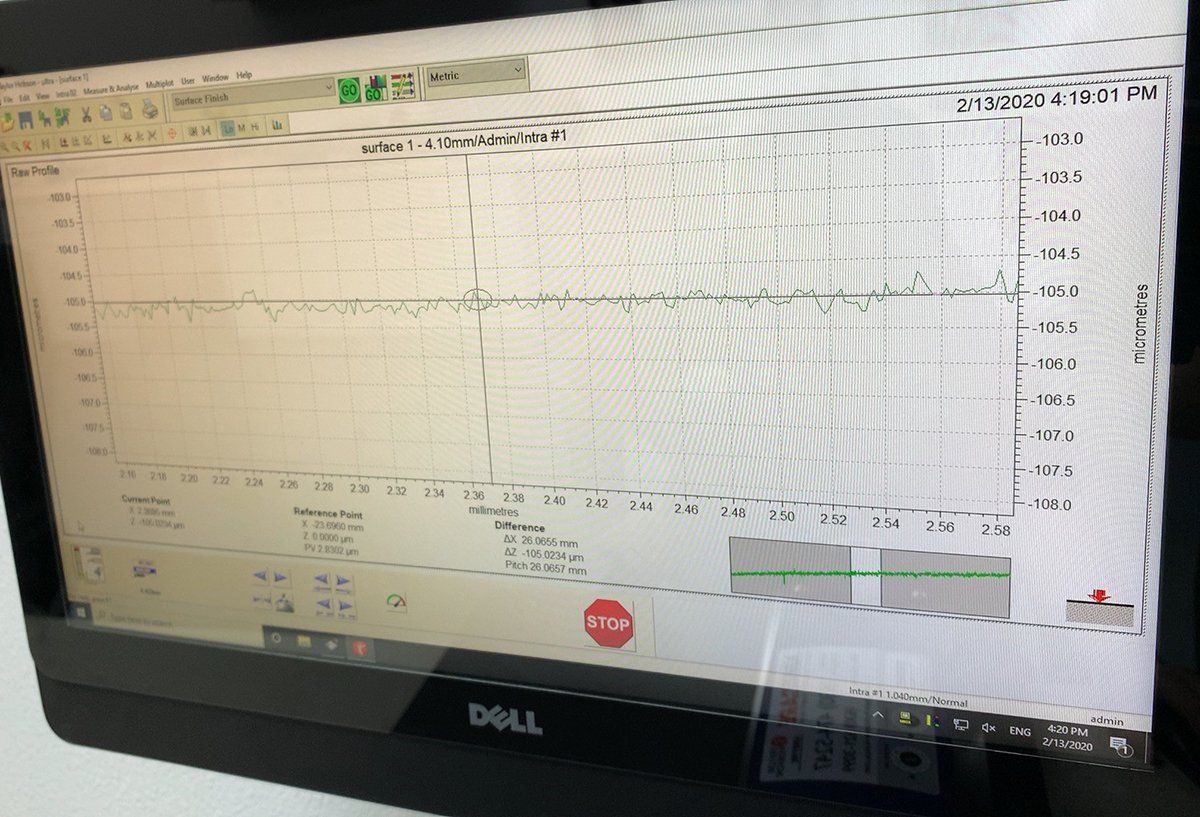

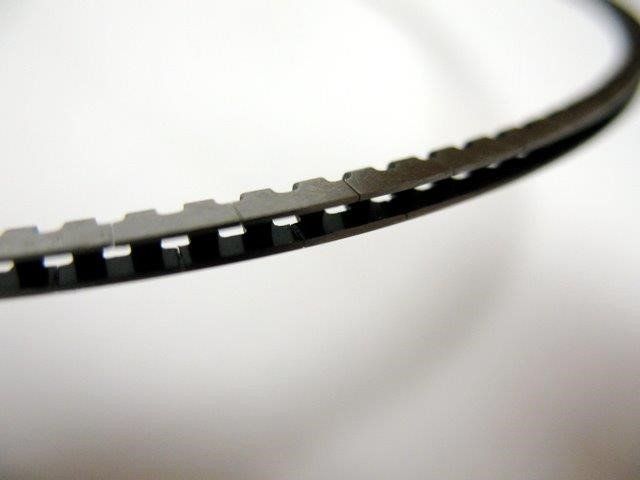

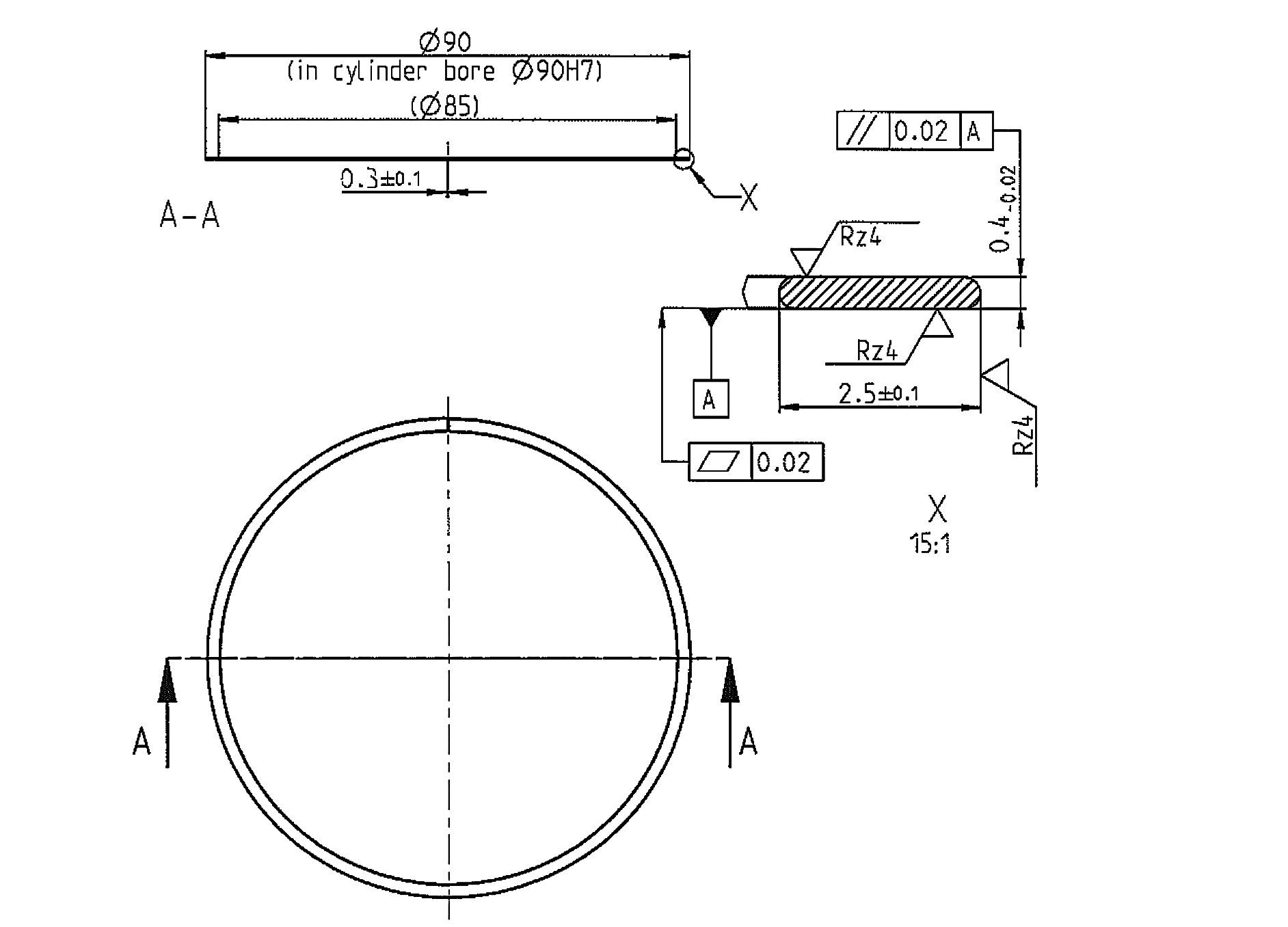

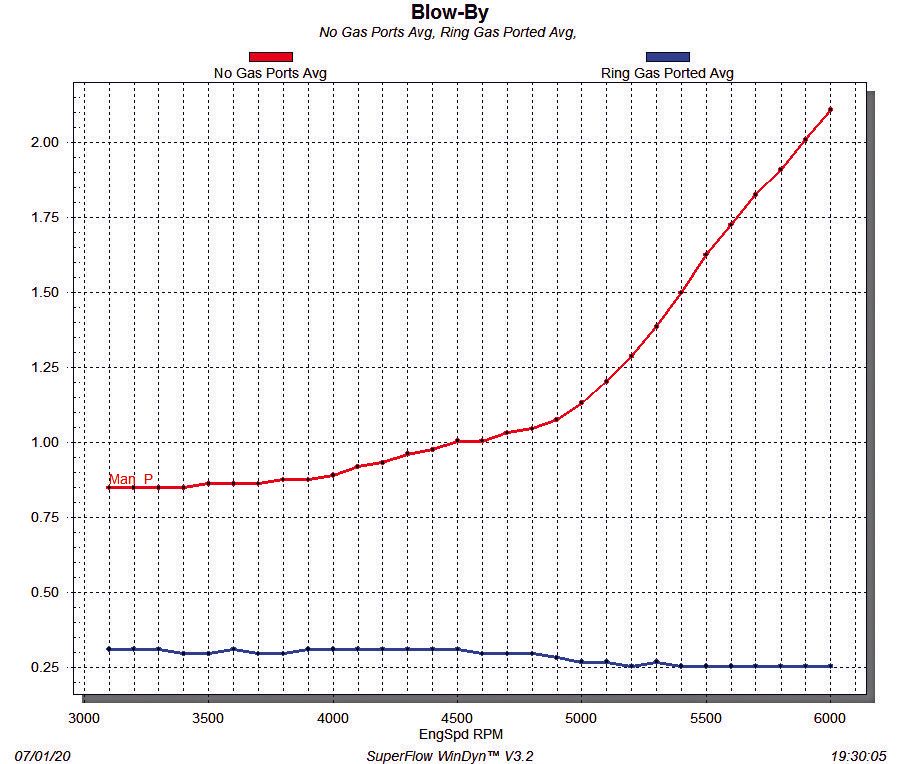

If you zoom in on the finish of a typical ductile iron piston ring, the surface looks like a sawtooth which results in leakage areas, albeit, tiny areas. When combustion pressures reach over 1500 psi, you can be sure those gasses are going to find any possible weak point and a standard ductile ring actually has many peaks and valleys forming leakage points. In the tests provided, you can see the results of a ductile iron ring compared to the surface of a Diamond Finish ring. Once you compare these variances next to each other, you really get an idea of how important the surface finish of the ring is for an effective seal.

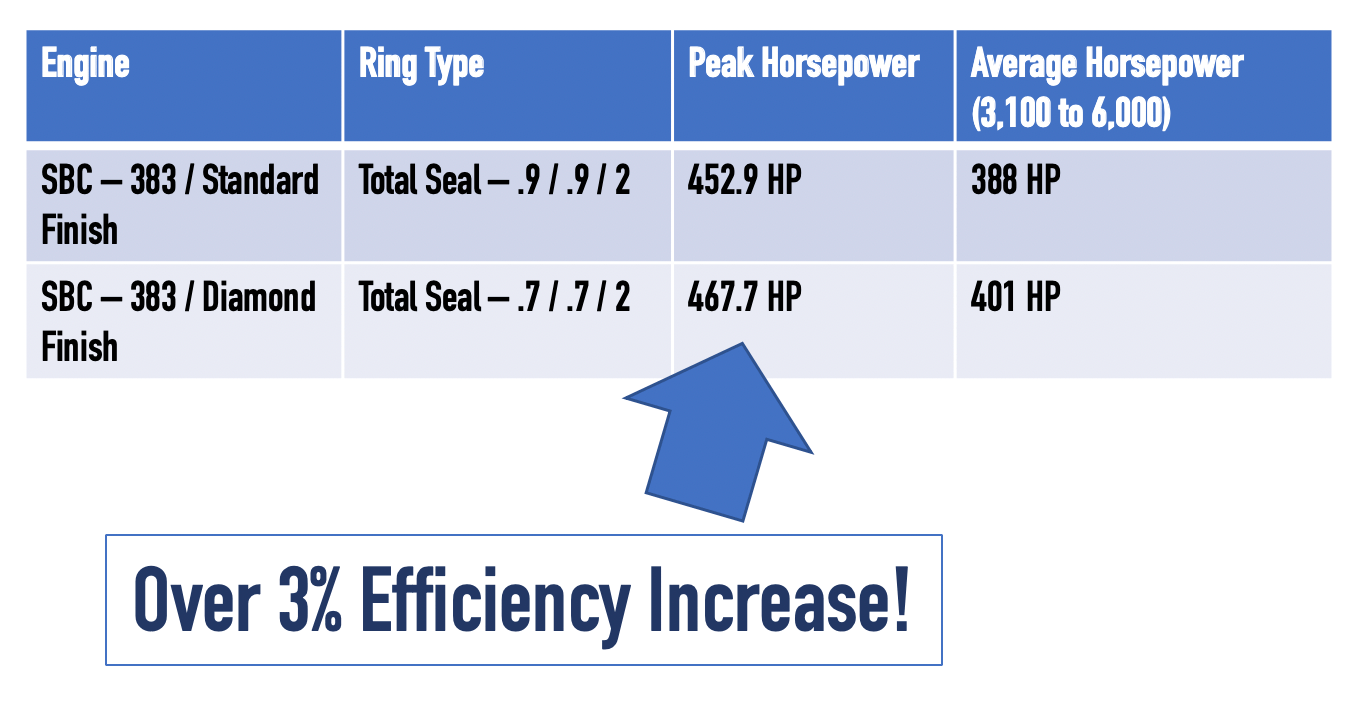

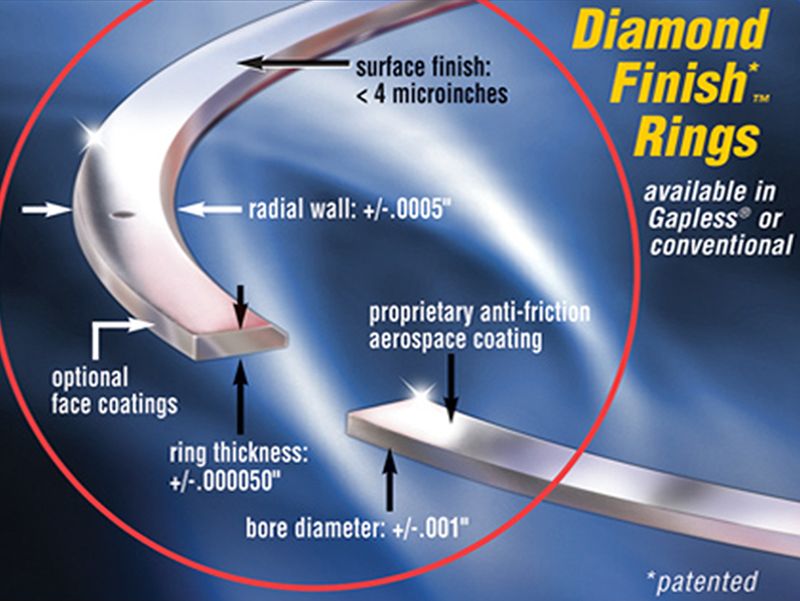

Aerospace materials, combined with Total Seal’s patented manufacturing processes allow them to produce a surface roughness of less than 4-microinches. This amazingly smooth surface seals to the piston ring flank creating the tightest, most effective seal possible. And where there’s a tight seal, there will be improved efficiencies resulting in increased performance.